| Murakami Seiki HOME > Cutting |

| |

From Trial Manufacture to a Mass Production

|

|

Enhance the accuracy of your precision parts? Need custom orders to develop new products? With the technical expertise obtained by processing various machining, Murakami Seiki perform the ultra-precision cutting process.

First, please contact with us! Especially if you are interested in the ultra-precision cutting including lathe, milling or three-dimensional machining.

We can provide a trial manufacture, small quantity from one lot, or a mass production.

In addition, we are able to assemble machineries which are designed to assemble high precision manufacturing parts. Being able to perform all the processes, we believe that, makes it possible to reduce costs and shorten the delivery date. We may be able to improve the quality of our workpieces as well.

|

|

|

|

| |

Examples of ultra-precision cutting process

|

| |

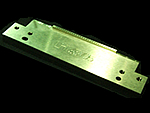

Example 1. Milling sus304 with flatness and parallelism of 3μm

|

Uses : Semiconductor producing equipment parts

Uses : Semiconductor producing equipment parts

Size : 30×100 (mm)

Materials : sus304 (stainless steel)

Precision : Flatness, parallelism of 3μm

Machining : Milling

Characteristic of the process : We perform 0.3mm-drilling on stainless steel by milling. |

|

|

| |

Example 2. Cutting large-sized metal molds and parts

|

Uses : Processing of the metal mold

Uses : Processing of the metal mold

Size : 500×700×300 (mm)

Materials : SKD-61 (hot dies steel)

Machining : Three-dimensional processing

We can also process cutting of large-sized products such as metal mold. Curved-surface machining and three-dimensional machining are available as well.

|

|

|

| |

Example 3. Cuttings of complex materials

|

Uses : Manufacturing a metal mold (when processing EDM)

Uses : Manufacturing a metal mold (when processing EDM)

Size : 200×200×400 (350) (mm)

Materials : Graphite

Precision : 3μm

Machining : Three-dimensional processing

Characteristic of the process : Graphite (allotrope of carbon) has a variety of characteristics and are known for the superior characteristic to metals such as copper and iron. However, because it is easy to crack, high-speed machining and microscopic cutting techniques are required to process this material. With our technical skills, we can provide a processing to complex materials which are difficult to machine.

|

|

|

|

Other examples of machining Other examples of machining

|

|

Our company makes sure that we have strict testing system and carry out inspections of goods by using measuring equipments in order to assure the precision of our cutting. We put our efforts to guarantee the qualities of each workpieces.

Quality Assurance System Quality Assurance System

|

| |

Processable materials and precision

|

| |

Processable Materials

Iron, Stainless, Aluminum alloy, Nickel alloy, Pure Titanium, Molybdenum, Tungsten, Sintered metal, Kovar, Dice steel, Heat-resisting steel, Carbide, Ceramics, etc.

Precision

We can provide the precision of 1 - 3 μm. With our strict quality testing system, not only the precision but we also guarantee the quality of our workpieces.

Acceptable Quantity

We can provide a trial manufacture, small quantity from one lot, or a mass production.

High-precision Assembly

Not only the machining, we can also perform assembling.

We have developed our own automatic machines for an efficiency improvement and to enhance the precision of assembling process.

High-precision assembly High-precision assembly

We can also process other kinds of materials which are not on the list above.

If you are interested in our machining, and are able to send us a plan, we can provide the proposal for the optimum materials for it as well. Feel free to contact us. We would always be happy to have any kinds of inquiries. |

|

| |

|

| |

Characteristics of Our Machining

|

| |

|

| High speed three-dimensional processing |

We manufacture ultra-precision metal molds and 3-D shaped parts by the high-speed 3-D processing with CAD/CAM.

|

|

| After-machining ; Heat treatment / Surface treatment |

We provide various types of techniques from processing to an after-processing surface treatment with our technical skills and expertise.

|

| Integrated system from planning to assembling |

We have well-established an integrated system which covers planning, testing, precision machining and assembling for ultra-precision machine parts.

|

|

|

|

| |

|

| |

| |

|

| These are only small parts of our work. If you are interested in our ultra-precision cutting and hope to get more information, go to page for inquires and feel free to contact us! We will do our best to meet your demands with technical skills and expertise of precision parts machining including each measuring instruments. |

|

|

|

|

|

| |

|

| |

|

|